Glass and Photography

by Kimberly Lyon

Ladybug Glass Studio

P.O. Box 124

Casco, WI 54205

United States

ph: 920-845-5858

kim

Ladybug Glass

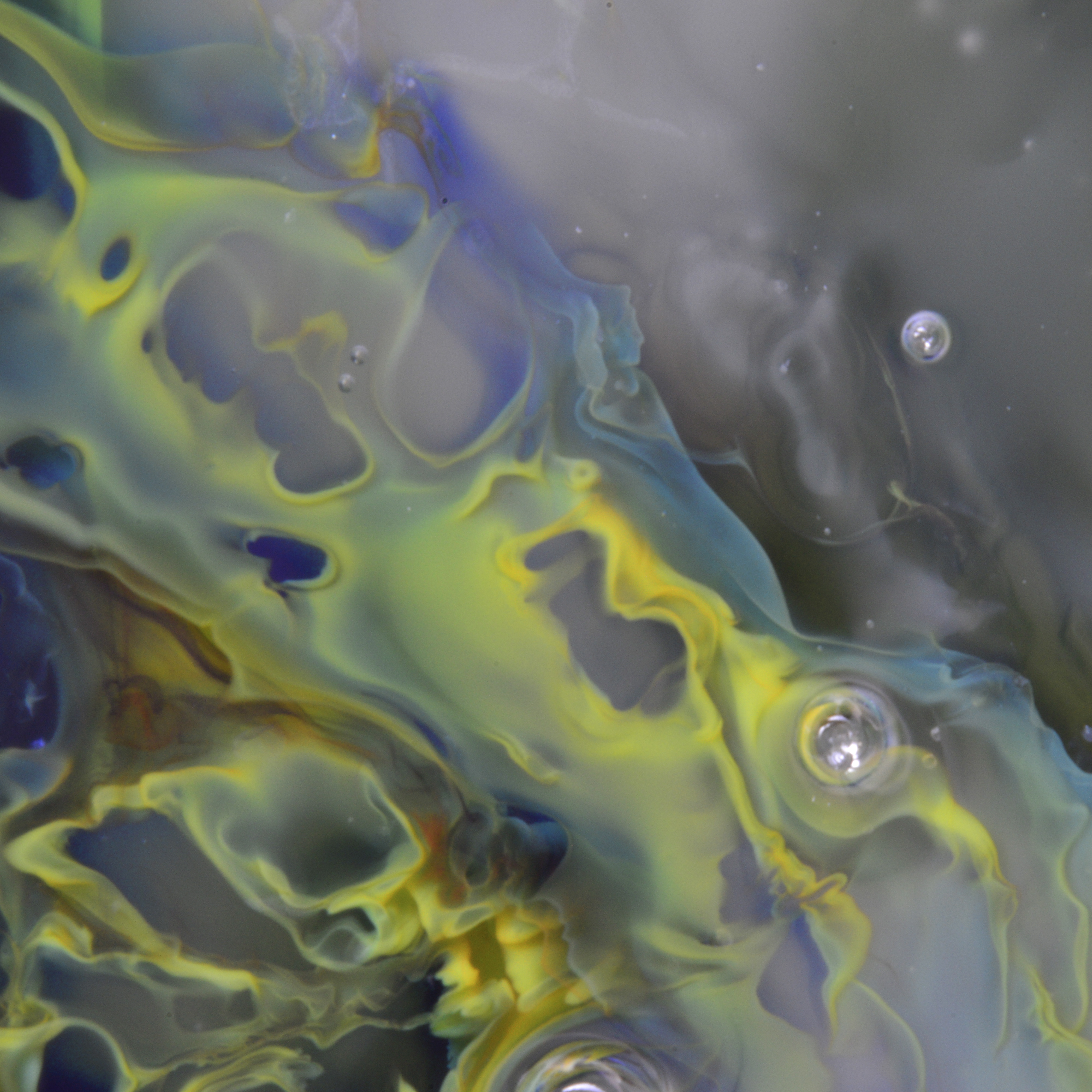

Ladybug Glass Studio is the Wisconsin business name that Kimberly has been using for her three dimensional functional fused glass pieces for more than 15 years. This is the name you will see associated with the vases, bowls, plates and other forms that are created by kiln-forming. Heating glass on forms in a kiln at temperatures high enough to either allow the glass to sag or slump into or over the form, or, at higher temperatures to actually melt individual pieces of glass into a single piece that can then be formed.

Additional photos will be added as available.

More Information

Contact Kimberly today!

We welcome your questions and queries. Please see the Contact page for complete contact information.

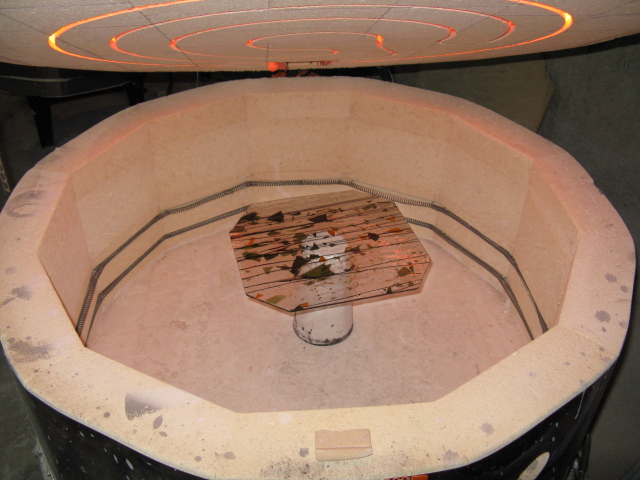

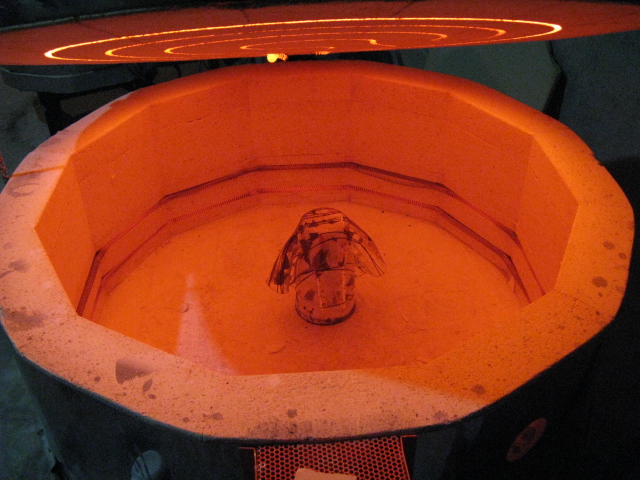

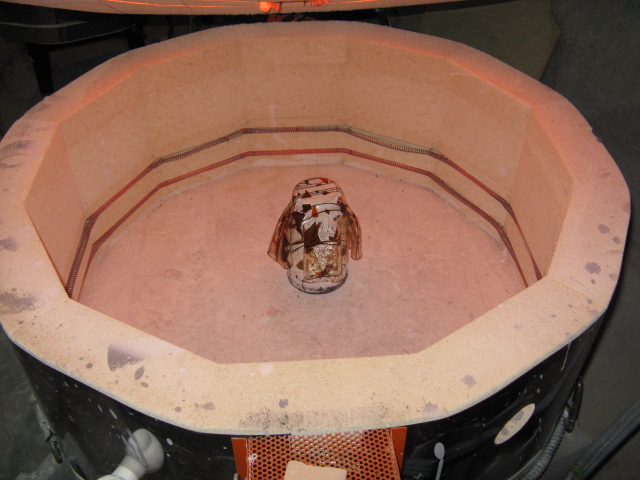

Forming a candle holder in the kiln. The glass is placed on a stainless steel form in the kiln and heated slowly to around 1300 degrees Farenheit. At about 1100 degrees the glass starts to sag and the folds begin to take shape. Once the candle holder reaches the desired shape the kiln is "crash cooled" to 1000 degrees to stop the movement of the glass. The kiln is then allowed to cool slowly and the glass is annealed. The entire process takes about 6-8 hours.

Ladybug Glass Studio

P.O. Box 124

Casco, WI 54205

United States

ph: 920-845-5858

kim